Precise temperature control is crucial for food safety, product quality, and operational efficiency in commercial refrigeration. This manual provides a comprehensive guide to understanding and optimizing True temperature control systems for optimal performance and troubleshooting.

1.1 Importance of Temperature Control in Commercial Refrigeration

Maintaining precise temperature control is essential for food safety, product quality, and operational efficiency in commercial refrigeration. Proper temperature management prevents bacterial growth, food spoilage, and health risks, ensuring compliance with health regulations. Temperature control systems like those in True refrigeration units help preserve the freshness and integrity of stored products, safeguarding customer satisfaction and business reputation. Improper temperature settings can lead to premature spoilage, financial losses, and potential legal issues. Conversely, accurate temperature control optimizes energy efficiency, reducing operational costs and extending equipment lifespan. By adhering to recommended temperature ranges, businesses ensure their refrigeration systems operate efficiently, maintain product quality, and support sustainability. In the foodservice industry, reliable temperature control is a cornerstone of success, directly impacting food safety, customer trust, and long-term profitability.

1.2 Brief Overview of the True Temperature Control Manual

This manual serves as a comprehensive guide for understanding, installing, and maintaining True refrigeration systems. Designed for both professionals and novices, it covers essential topics such as temperature control principles, system components, and troubleshooting techniques. The manual includes detailed instructions for adjusting settings, performing routine maintenance, and resolving common issues. With over 30 pages of content, it provides in-depth insights into the operation of True refrigeration units, ensuring optimal performance and longevity. Key sections address energy efficiency, compliance with health regulations, and high-altitude adjustments. Practical tips and step-by-step guides empower users to confidently manage their equipment. Whether you’re handling basic operations or advanced repairs, this manual offers a clear, user-friendly approach to mastering True temperature control systems, supported by diagrams and real-world applications.

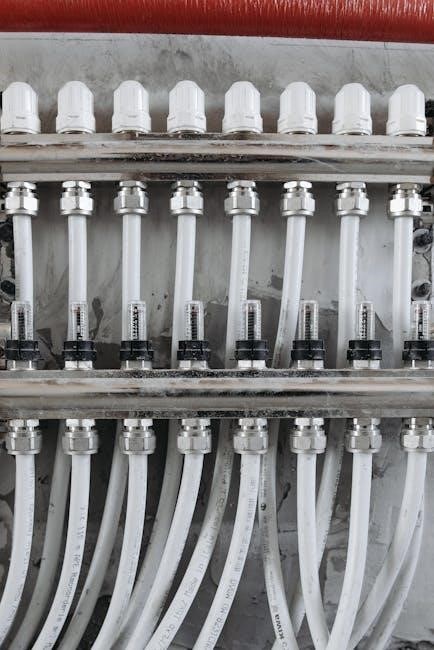

Components of the Temperature Control System

The system includes temperature sensors, a control unit, compressor, fan, and defrost timer, each playing a vital role in maintaining precise temperature regulation within commercial refrigeration units.

2.1 Temperature Sensors and Their Role

Temperature sensors are critical components of the True temperature control system, continuously monitoring the internal temperature of the refrigeration unit; These sensors provide accurate readings to the control unit, ensuring precise regulation of cooling processes. Their role is essential for maintaining consistent temperatures, which is vital for food safety and product quality. By detecting even slight temperature changes, sensors enable the system to adjust operations dynamically, optimizing energy efficiency and performance. Proper placement and calibration of sensors are crucial to ensure reliable data transmission. Different types of sensors, such as thermistors or thermocouples, may be used depending on the specific requirements of the refrigeration unit. Regular inspection and maintenance of sensors are recommended to prevent accuracy issues and ensure uninterrupted system operation. Their functionality is fundamental to the overall efficiency and reliability of the temperature control system in commercial refrigeration applications.

2.2 The Temperature Control Unit: Brain of the System

The temperature control unit is the central command center of the True temperature control system, responsible for processing data from temperature sensors and regulating the refrigeration cycle. It acts as the brain, interpreting temperature readings and sending signals to components like the compressor and fan to maintain the desired temperature. Advanced units feature digital displays and intuitive controls, allowing users to set precise parameters and monitor system performance. The control unit ensures efficient operation by adjusting cooling output based on factors like ambient temperature and load. It also manages defrost cycles to prevent ice buildup, optimizing energy use and system longevity. Proper calibration and operation of the control unit are essential for maintaining consistent temperatures, ensuring food safety, and reducing energy consumption. Regular updates and maintenance of the control unit are recommended to ensure optimal performance and adaptability to varying operational demands.

2.3 Compressor and Fan: Key Players in Cooling

The compressor and fan are vital components in the True temperature control system, working together to achieve efficient cooling. The compressor circulates refrigerant through the system, compressing it to facilitate heat transfer. It is the heart of the refrigeration cycle, driving the process that removes heat from the cabinet. The fan, on the other hand, ensures proper airflow across the evaporator and condenser coils, enhancing heat exchange efficiency. Together, they maintain consistent temperatures and prevent overheating. The compressor operates under the control of the temperature control unit, adjusting its output based on temperature readings. The fan continuously circulates air within the cabinet, ensuring even cooling and preventing hot spots. Both components are essential for maintaining optimal performance, and their failure can lead to temperature fluctuations and system inefficiency. Regular maintenance, such as checking for blockages and ensuring proper lubrication, is critical to their longevity and effectiveness.

2.4 Defrost Timer and Its Function

The defrost timer is a critical component in the True temperature control system, responsible for managing the defrost cycle. Its primary function is to prevent excessive ice buildup on the evaporator coil, which can impede airflow and reduce cooling efficiency. By cycling the defrost process, the timer ensures that the evaporator operates optimally, maintaining consistent temperatures and preventing system strain. The defrost timer works in conjunction with the temperature control unit, activating the defrost cycle at predetermined intervals. This process involves shutting off the compressor and allowing the evaporator to defrost, either through electric heat or natural thawing, depending on the system design. Proper functioning of the defrost timer is essential to maintain energy efficiency and prevent premature wear on the system. Regular checks of the defrost timer ensure it operates correctly, avoiding issues like frost accumulation or excessive energy consumption. This component is integral to the overall performance and longevity of the refrigeration system.

Understanding the System’s Operation

The True temperature control system maintains consistent temperatures through coordinated components, ensuring food safety and energy efficiency. Understanding its operation is vital for optimal performance.

3.1 General Sequence of Operation

The True temperature control system operates through a systematic sequence to maintain consistent temperatures. It begins with the temperature sensor monitoring the cabinet’s internal temperature and relaying data to the control unit. If the temperature exceeds the setpoint, the control unit activates the compressor and fan to initiate the cooling cycle. The compressor circulates refrigerant, while the fan ensures even air distribution. Once the desired temperature is reached, the system enters a standby mode, with periodic checks to ensure stability. If ice buildup occurs, the defrost timer initiates the defrost cycle. This sequence ensures efficient operation, maintaining optimal conditions for food safety and energy efficiency. Regular monitoring and adjustments are recommended to adapt to environmental changes, ensuring the system runs smoothly and effectively.

3;2 Interaction Between Components

The interaction between components in True temperature control systems ensures precise temperature regulation. The temperature sensor continuously monitors the cabinet’s internal temperature and relays data to the control unit. The control unit processes this information and activates the compressor and fan when cooling is needed. The compressor circulates refrigerant through the system, while the fan distributes cold air evenly. The defrost timer interrupts the cooling cycle to prevent ice buildup on the evaporator coil, ensuring efficient operation. Each component works in harmony, with the control unit acting as the central hub. If one component malfunctions, it can disrupt the entire system, leading to temperature fluctuations. Understanding these interactions is key to diagnosing issues and maintaining optimal performance. Proper communication between parts ensures energy efficiency, food safety, and consistent temperature control, making the system reliable for commercial refrigeration needs.

Adjusting Temperature Control Settings

Adjusting settings involves selecting the desired temperature using a dial or digital display, typically ranging from 1 to 5. Start with a moderate setting and monitor temperature with a thermometer to ensure accuracy and optimal performance.

4.1 Step-by-Step Guide to Adjusting Settings

Adjusting the temperature control settings on your True refrigeration unit is a straightforward process that ensures optimal performance and food safety. Follow these steps:

- Locate the temperature control. The control is typically a dial or digital display on the front or side of the unit.

- Set the desired temperature. Turn the dial or use the digital interface to select the preferred temperature. For most units, the range is from 1 (coldest) to 5 (warmest).

- Monitor the temperature. Use a thermometer to verify the internal temperature. Allow the unit to run for several hours to stabilize.

- Adjust as needed. If the temperature is too high or low, make small adjustments and recheck after a few hours.

- Refer to the manual. For high-altitude settings, consult the True temperature control manual for specific guidance.

By following these steps, you can ensure your True refrigeration unit operates efficiently and maintains the ideal temperature for food safety and preservation.

4.2 High-Altitude Adjustments

In high-altitude environments, True refrigeration units may require specific adjustments to maintain optimal performance. Thinner air can affect the system’s cooling efficiency, potentially leading to temperature fluctuations. To address this, True recommends adjusting the temperature control settings to compensate for the lower air pressure and density.

Start by referring to the True temperature control manual for altitude-specific guidelines. Typically, high-altitude settings involve lowering the temperature set point to achieve the desired internal temperature. This ensures the unit operates efficiently without overworking the compressor or causing excessive energy consumption.

After making adjustments, monitor the unit’s performance closely. Use a thermometer to verify the internal temperature and make fine-tuning adjustments as needed. Proper high-altitude calibration ensures food safety, prevents equipment strain, and maintains optimal refrigeration performance.

Troubleshooting Common Issues

Identify temperature fluctuations, compressor malfunctions, or defrost cycle problems by checking thermostat settings, condenser coils, and sensors. Refer to the manual for guided steps to resolve issues effectively.

5.1 Identifying Common Problems

Common issues in True temperature control systems include temperature fluctuations, compressor malfunctions, and defrost cycle problems. These issues often stem from faulty thermostats, blocked condenser coils, or sensor inaccuracies. Users may notice symptoms like uneven cooling, unusual noises, or ice buildup. To identify problems, start by checking the thermostat settings and ensuring proper calibration. Inspect condenser coils for dust or debris, which can impede heat dissipation and reduce efficiency. If the compressor is malfunctioning, it may fail to cool or operate excessively. Defrost cycle issues can lead to excessive ice buildup or water leakage. Regularly monitoring system performance and addressing minor issues promptly can prevent major breakdowns. Always refer to the True temperature control manual for specific troubleshooting guidance tailored to your model. If problems persist, contacting True Manufacturing’s technical support is recommended for expert assistance and parts replacement.

5.2 Advanced Troubleshooting Techniques

For advanced troubleshooting, users can employ system-wide diagnostics to pinpoint issues beyond basic malfunctions. Start by analyzing temperature trends over time to identify patterns in fluctuations. Check the accuracy of temperature sensors by comparing their readings with a reliable external thermometer. Inspect electrical connections and wiring for damage or corrosion, as these can disrupt communication between components. Additionally, perform a detailed examination of the refrigeration cycle, including the compressor’s performance and the flow of refrigerant. Advanced users may also benefit from adjusting system parameters, such as defrost cycle timing or fan speed, to optimize performance. For high-altitude installations, ensure settings are calibrated to account for lower air pressure. If issues persist, advanced diagnostic tools or software provided by True Manufacturing can help identify root causes. Always consult the True temperature control manual for model-specific guidance and to access detailed troubleshooting charts and flow diagrams.

Maintenance and Care

Regular maintenance is essential to ensure optimal performance and longevity of your True temperature control system. Clean condenser coils, inspect door seals, and follow the recommended maintenance schedule outlined in the manual for best results.

6.1 Cleaning Condenser Coils

Cleaning condenser coils is a critical maintenance task for ensuring efficient operation of your True temperature control system. Over time, dust and debris accumulate on the coils, reducing their ability to dissipate heat effectively. This can lead to increased energy consumption and reduced cooling performance. To clean the coils, turn off the power to the unit and carefully remove any protective coverings. Use a soft-bristle brush or a vacuum cleaner with a gentle suction setting to remove dirt and dust. For more stubborn buildup, a mild detergent and water solution can be applied, but ensure the coils are rinsed thoroughly and allowed to dry before restarting the unit. Regular cleaning, ideally every 1-3 months depending on usage and environment, will maintain optimal performance and extend the lifespan of your refrigeration system. Neglecting this step can lead to premature wear on the compressor and increased operational costs.

6.2 Regular Maintenance Schedule

A well-structured maintenance schedule is essential for the longevity and efficiency of your True temperature control system. Regular inspections and maintenance tasks prevent potential issues before they arise. Start with daily checks, such as ensuring doors seal properly, monitoring temperature readings, and listening for unusual noises. Weekly tasks include cleaning the condenser coils to maintain airflow and inspecting the drain line for blockages. Monthly, check the door gaskets for wear and tear, and verify that the evaporator fan is functioning correctly. Every three months, inspect the defrost cycle to ensure it operates effectively, and clean the evaporator coils if necessary. Annually, schedule a professional service to inspect the compressor, refrigerant levels, and electrical connections. Adhering to this maintenance schedule ensures optimal performance, reduces energy consumption, and extends the lifespan of your True refrigeration equipment, safeguarding your investment and maintaining food safety standards. Consistency is key to preventing unexpected breakdowns and ensuring seamless operation.

Best Practices for Optimal Performance

Monitor temperature settings regularly, ensure proper door sealing, and conduct routine inspections to maintain efficiency. Minimize door openings and avoid overstocking to optimize performance and energy savings, ensuring compliance with health standards.

7.1 Energy Efficiency Tips

Regularly cleaning condenser coils improves heat dissipation, reducing energy consumption. Adjusting temperature settings to match actual storage needs prevents overcooling, optimizing energy use. Ensuring proper door sealing minimizes cold air loss, enhancing efficiency. Maintaining optimal stock levels avoids overloading, which strains the system. Scheduling periodic inspections of compressors and fans ensures they operate efficiently. Using smart temperature control settings during off-peak hours reduces energy demand. Implementing these practices not only lowers operational costs but also extends equipment lifespan, promoting sustainability and adherence to health regulations.

7.2 Compliance with Health Regulations

Compliance with health regulations is essential for food safety and business continuity. Consistent temperature control prevents bacterial growth, ensuring food remains safe for consumption. Regular system checks and accurate temperature monitoring are vital for adhering to health codes. Maintaining records of temperature settings and system performance provides documentation for inspections. Training staff on proper temperature management ensures compliance with guidelines. The True temperature control system is designed to meet strict health standards, offering precise control and reliable operation. By following the manual’s guidelines, businesses can ensure their refrigeration systems align with regulatory requirements, safeguarding food quality and customer health. This not only prevents potential fines but also upholds the establishment’s reputation for safety and quality. Proper compliance practices are integral to the success of food service operations, and the True system supports these efforts seamlessly.